Major Household Appliances, Data Conversion, and Service Calls

By Dennis D. McDonald

A visit from an appliance repair service this week to my home brought back some pleasant memories.

Years ago I had the good fortune to work for a company that had pioneered commercial applications of CD-ROM technology. The developers who worked for the company were brilliant. One area where we excelled was development of CD-ROM based illustrated parts catalogs. The catalogs cleverly combined powerful search and retrieval technology with the ability to locate, retrieve, and display illustrations on screen in ways that warmed the heart of repair technicians everywhere; these data were usually integrated in some fashion with a customer support or parts ordering system.

I remember the look of immediate value recognition when a field service technical saw how easy it would be to carry around thousands of pages of parts catalogs, wiring diagrams, and repair manuals on a stack of CD-ROM’s. No more paper manuals taking up space in their repair trucks. No more trips back and forth to the repair truck from the work site in bad weather. No more trips up to the mezzanine engineering drawing collection from the factory floor when an assembly line device broke down.

One of my jobs was managing data conversion on these projects. We had an in-house scanning operation where we could batch-convert paper diagrams to digital image files and link these files to parts, model, and other data extracted from other sources.

On one project where we converted several million pages we had to constantly replace the scanning machines’ rubber rollers that grabbed stacked pages. Many of the documents were declassified German WWII technical reports destined for a refrigerator size 12” optical platter juke box. The documents were covered with plaster dust; the abrasive dust constantly chewed up the rubber rollers. We ended up setting up a “clean room” with industrial vacuum cleaners to clean the pages prior to scanning. “High tech” was fun in those days!

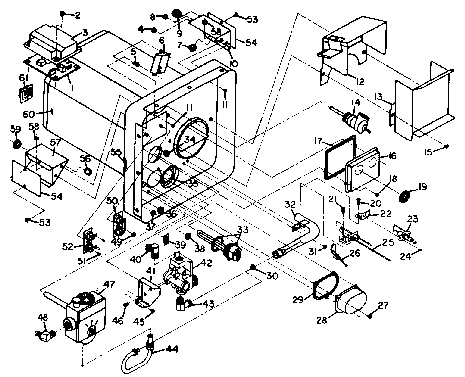

Working for clients like GE Appliances and Whirlpool I was constantly amazed at the variety of washing machines, gas ranges, and dryers and their sub assemblies that needed to be supported. One goal was to convert the parts diagrams to electronic form and make them retrievable via the service call center’s network via part, assembly, subassembly, model number, serial number — you name it, we’d build an index for it.

The necessary data conversion projects were usually major undertakings since, even when the original data was in some sort of electronic form. parts data usually weren’t compatible. Most of the companies we worked for had been built up from multiple companies over many years and still maintained separate engineering departments, manufacturing lines, bills of material, and incompatible parts numbering schema. Numbering variations easily handled by human technicians we had to smooth out via software conversion and editing in order to provide consistency to the indexing. Woe betide anyone who failed to detect a duplicate part number coming in from two separate factories describing two completely different parts!

These memories came back this week while I waited for the appliance repair guy to arrive.

A couple of months ago one of the hinges had failed on my kitchen gas range door and, being the “fix it myself” guy that I am, I proceeded to locate the part online, order it, and install it myself.

It didn’t work. The gas range door over time failed to close tightly. What was worse, the latch for the “self cleaning” feature would not clamp tightly in the open or closed position.

Something had to give and I was drawing a blank on my home grown repair techniques. I threw in the towel and called a national appliance repair service after locating the hard to find model and serial number on the gas range. (I found the location of the label courtesy of one of the many web based appliance repair sites that now exist.)

I scheduled the service call online and was given a 4 hour window one week later. The scheduling process itself was simple, though the text box where I described the problem on the web site seemed to limit itself to 50 characters of text.

The repair technician did not come at the scheduled time, nor did he or she call to let me know about the actual schedule. I called the national 800 number and they text-messaged the technician, who called two hours later to say he was 5 minutes away. According o his GPS he said he would be able to locate my house.

He arrived and took a look at the gas range. “Where’s the model number?” he asked. I showed him and he typed the number into his hardened wireless laptop, well worn with a small antenna sticking out the top.

He couldn’t find the gas range listed. Finally he found it - he and I had both interpreted the “S” in the model number as a “5” — a reasonable a error given the difficult to read model number label was inside the top of the range under the cover, tucked away in a corner.

Finally, he found the parts listing. On his laptop’s screen I saw displayed a beautiful parts explosion diagram, just like the ones I remembered from my work with GE and Whirlpool. I left him to his devices and went back upstairs to my office for a phone call. When I came downstairs I found him on his cell phone with a colleague. He had taken the range door off its hinges and was testing them. They both had the proper tension. I could tell from the conversation he was having he was having some difficulty figuring out the problem.

I went back upstairs. A while later, returning to the kitchen, he was off the phone and typing into his wireless laptop. “You need two new hinges,” he said, “that’s $25 apiece.” “OK,” I said. “I thought you said the tension was OK on the spring loading of the hinges? ” I asked, and he sort of shook his head. “Nope, they just won’t shut it tight.”

I thought, OK, he knows what he’s talking about.

“Have you tested the spring on the left hand side,” I asked. That was the one I had replaced with a similar type. He bent down and poked around underneath. “You had to bend it to make it fit?” Yes I replied — that was the only way to get the proper tension. He looked at me and asked, “Do you think I should order a spring?”

I looked at him. I’m no mechanical engineer but I could see how this was going. What if the new hinge arrived and the spring wasn’t right?

“Sure, order a new spring,” I said, and he went back to his laptop and typed again. “That will be another 8 dollars.”

I bent down and opened and closed the range door. Opening it all the way I felt the silver metal covered gasket that surrounded the interior opening to the oven. “How about this gasket,” I asked, “could it be preventing the door from closing? This part along the bottom is hard, not soft.”

He felt the gasket. “Yep, that gasket is hard all right.”

I asked him, “Could that prevent the door from closing all the way?” He felt the gasket and looked up at me. “Do you want me to order a new gasket?”

Sigh. He typed in his wireless laptop. “The gasket is $85.”

“Sure, order it.”

He took my credit card, ordered the parts, and printed out the ticket for me to sign on his portable printer. “The parts will be delivered here. Call our 800 number when they arrive and we’ll come back and install them. That service call will be another $62.” He departed.

I looked at the gas range and wondered, “Have I diagnosed this problem correctly?”

Copyright (c) 2007 by Dennis D. McDonald